We manufacture high-quality rubber and plastic products and assemblies that go into items such as plumbing products, water softeners, food manufacturing equipment, electronics, health care products, toilets and tank trim, boilers, HVAC equipment, transportation equipment and pump systems. Our customers count on us because we offer:

- A large selection of rubber, plastic and specialty material formulations to choose from, including certified elastomers that meet highly specialized performance requirements

- On-site chemists who can formulate a custom material if none of our more than 2,000 active formulations meet your needs

- Extensive product design engineering, tooling and manufacturing expertise that let us create precision molded products and assemblies

- Continually improving lean manufacturing processes that enable us to minimize waste and costs

- Processes that quickly move parts from conception to completion

- An array of manufacturing services, including injection and conventional rubber molding; plastic molding; lathe cutting, die cutting and finishing services; and assembly and packaging operations

A History of Innovation

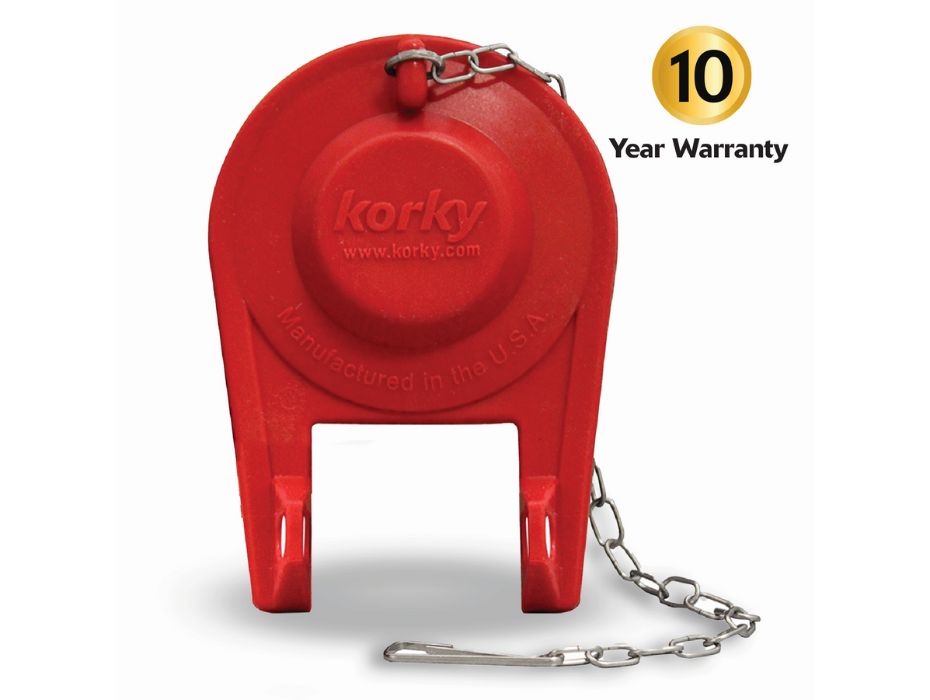

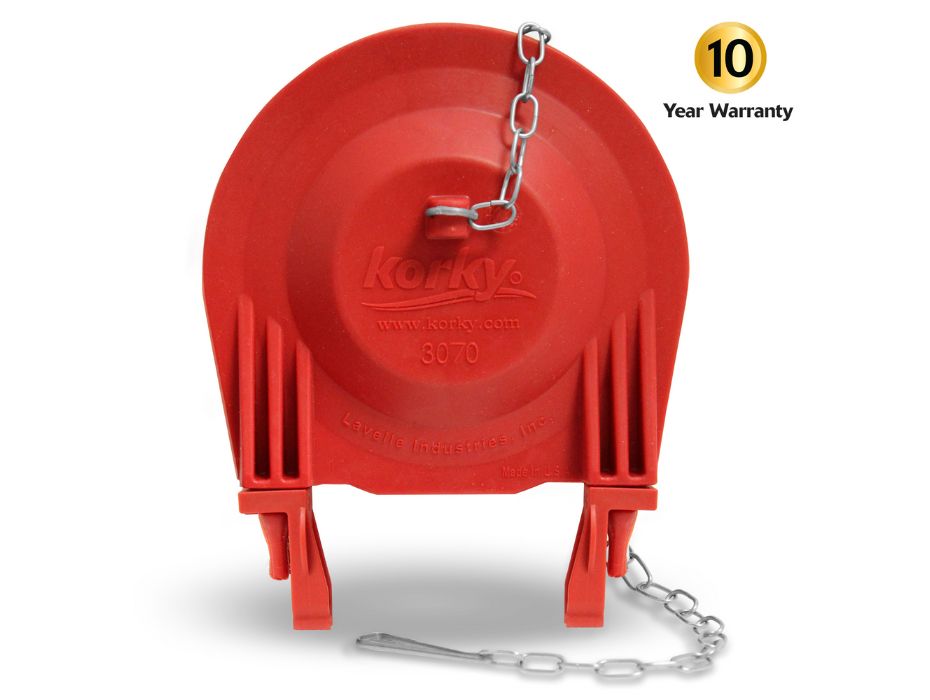

In 1954, we designed the first toilet flapper and this technology is still being used today. We have continued to be an engineering leader for our customers, designing products and solving problems. We accomplish this, not only from part design, but also material development, to meet the ever-changing needs of our customers. As we grow, we continue to invest in our equipment; we have new mixing equipment, new measuring equipment, refurbished and new presses. All to give our customers the best service and innovation a rubber and plastic manufacturing company has to offer.

To discuss your next project or to learn more about how we can help you, please contact us today.